What are you looking for? A price quote within 24 hours!

Clean working according to Grade 2 and Grade 4

Some customers, especially OEMs, have special cleanliness requirements towards suppliers for:

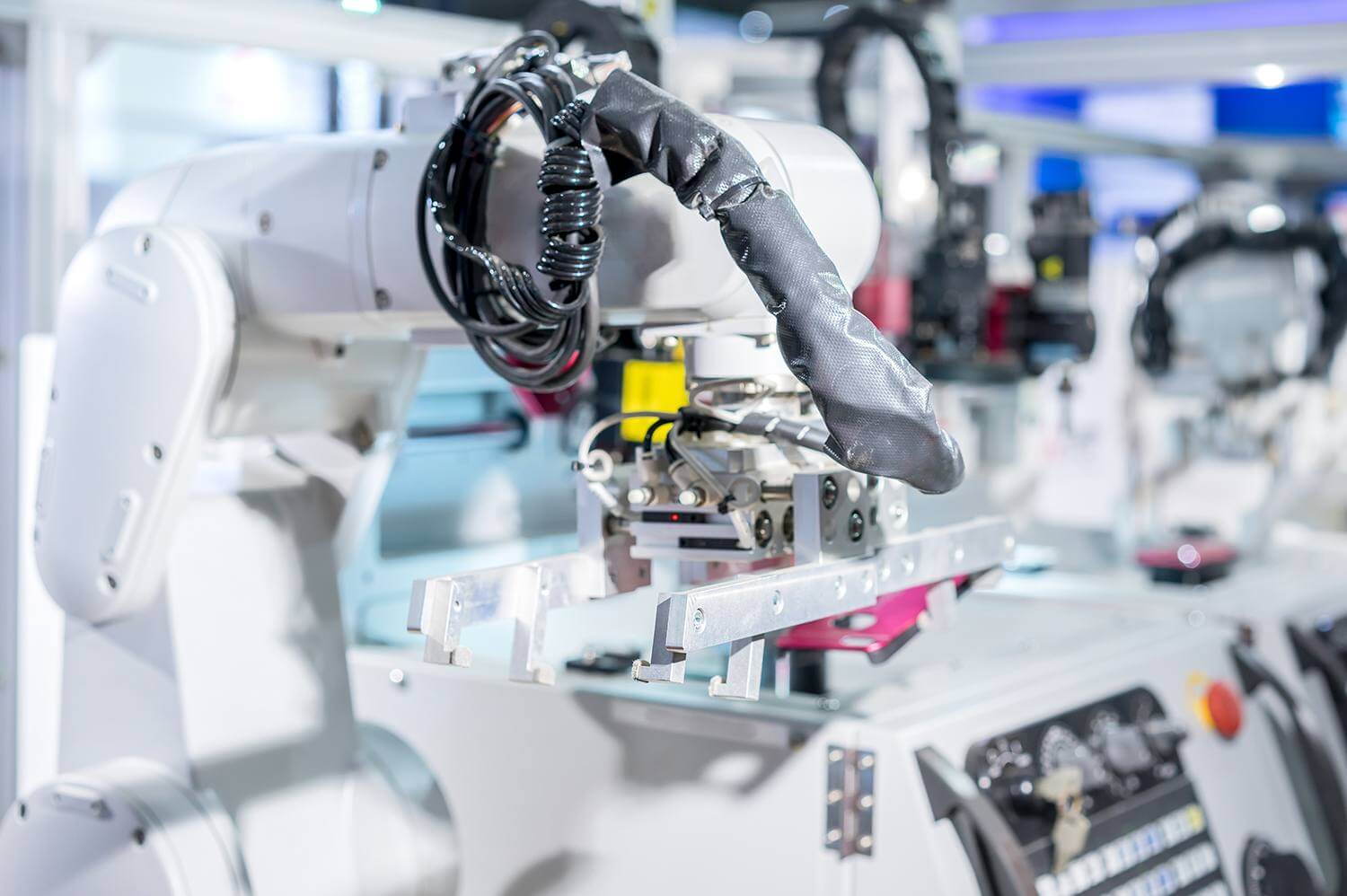

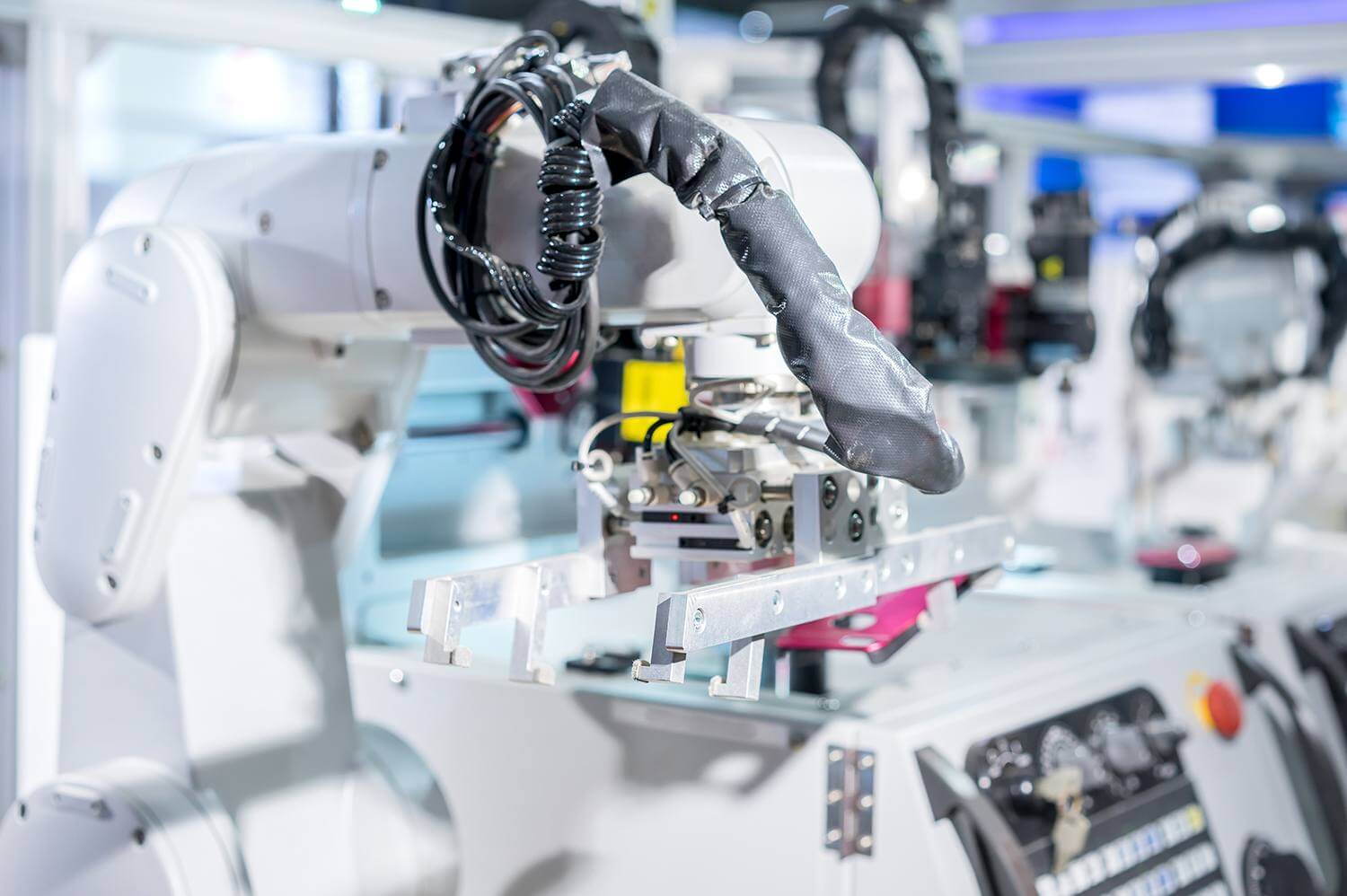

– Machining products

– Cleaning products

– Assembling (sub)assemblies

– Packaging products

We have all the necessary knowledge, facilities and partners to meet this demand.

Cleanliness

Cleanliness involves (micrometer) small particles, molecular contaminants (water, hydrocarbons, etc.) and outgassing by metals (think of the various types of steel). Clean products are particularly in demand for vacuum applications in markets such as semicon, analytical and space.

Cleanliness

Cleanliness involves (micrometer) small particles, molecular contaminants (water, hydrocarbons, etc.) and outgassing by metals (think of the various types of steel). Clean products are particularly in demand for vacuum applications in markets such as semicon, analytical and space.

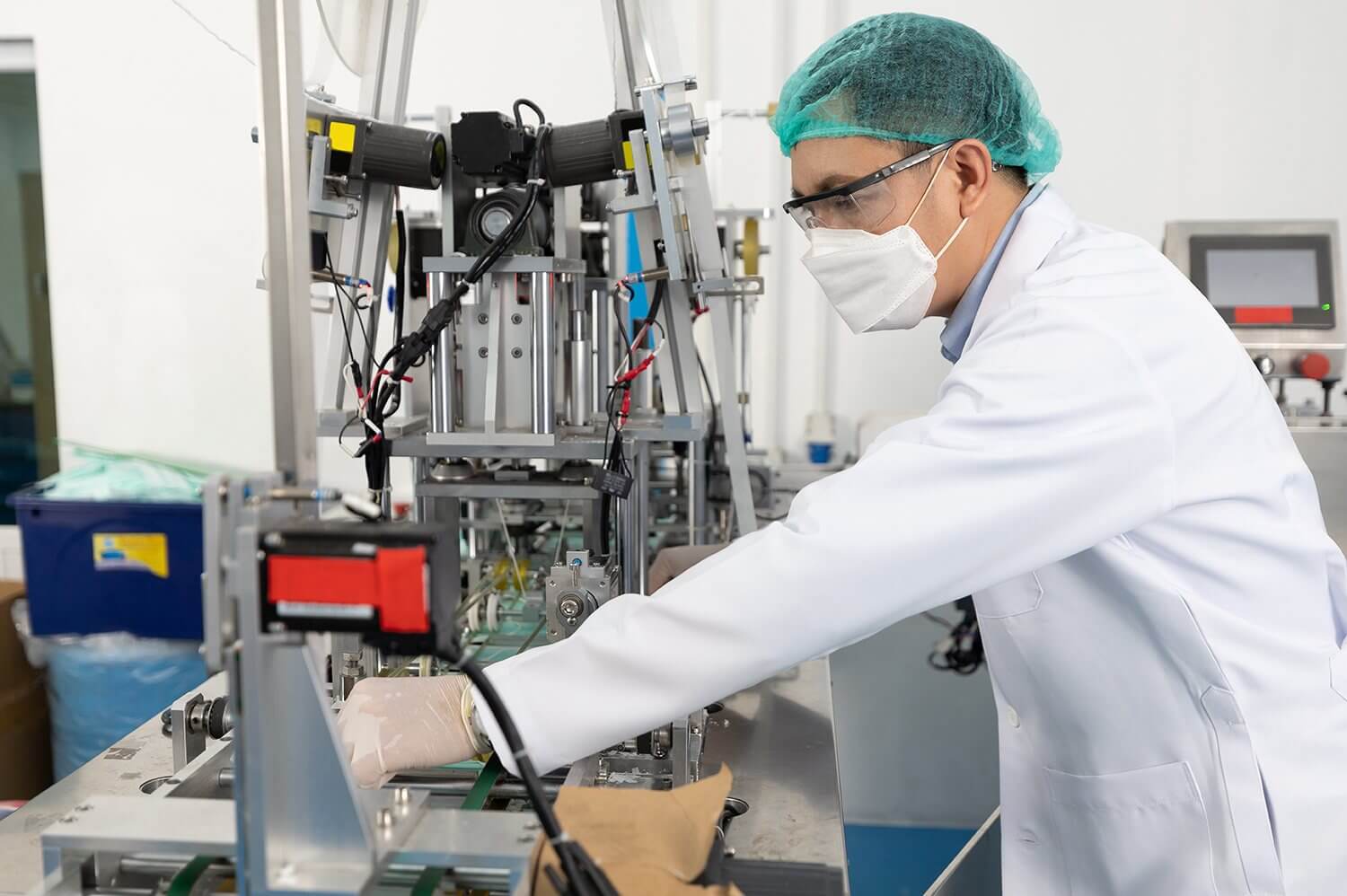

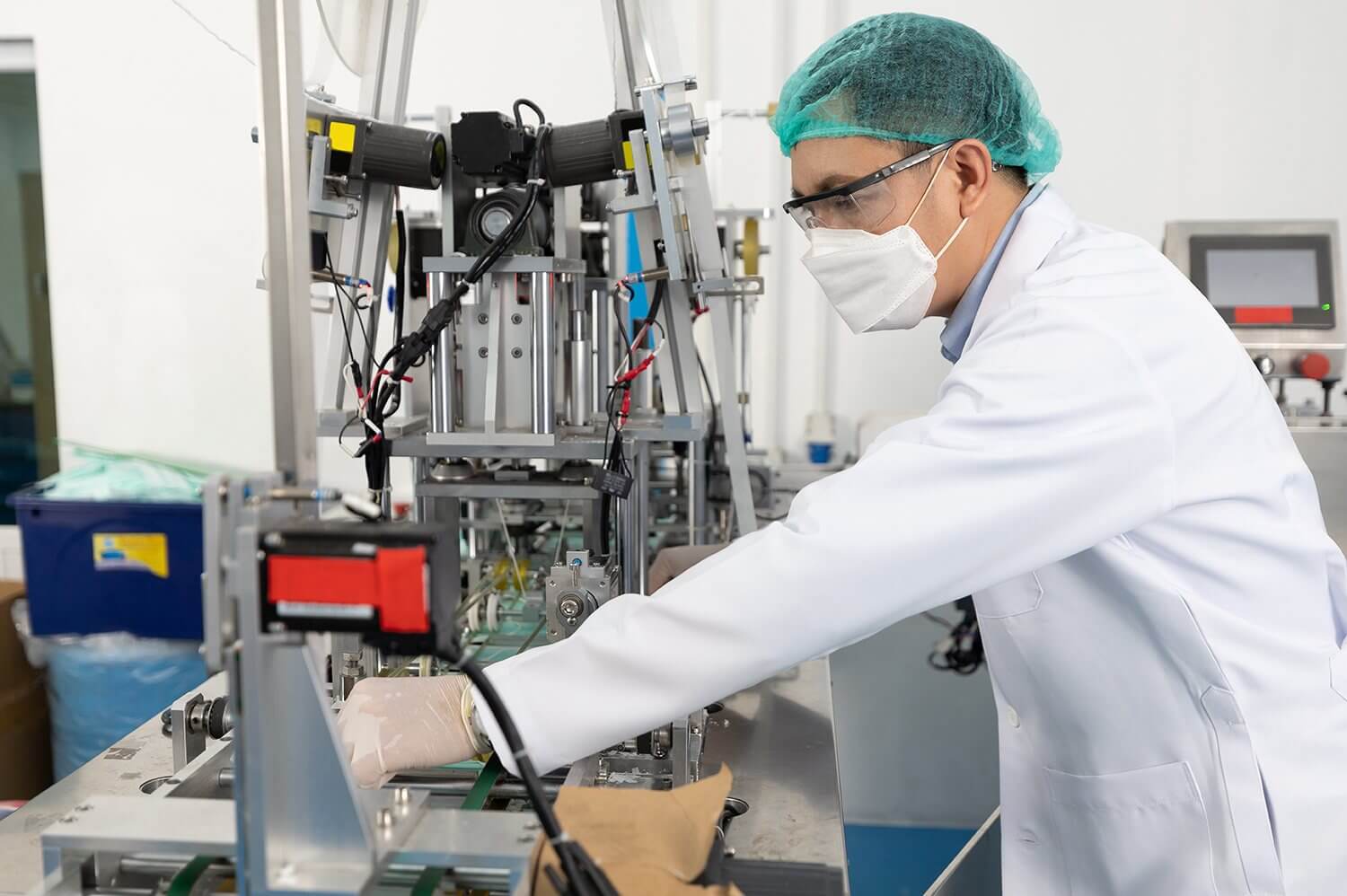

Prevention and cleaning

When speaking of cleanliness, it may refer to both the cleanliness of products and a clean way of working. After all, cleanliness starts with prevention: preventing contamination by working in a clean environment, such as a cleanroom, with protective clothing and following strict procedures. The minimal contamination that can still occur requires cleaning of the products. This must be done with the utmost care to meet the cleanliness requirements and to prevent damage to the products.

Prevention and cleaning

When speaking of cleanliness, it may refer to both the cleanliness of products and a clean way of working. After all, cleanliness starts with prevention: preventing contamination by working in a clean environment, such as a cleanroom, with protective clothing and following strict procedures. The minimal contamination that can still occur requires cleaning of the products. This must be done with the utmost care to meet the cleanliness requirements and to prevent damage to the products.

Cleanliness grades

As a forerunner in this field, ASML has defined so-called cleanliness grades; in particular Grade 2 and Grade 4 are common. The customer prescribes the classification and thus the cleanliness requirements. This includes, for example, the coolants and cleaning agents to be used, but also how products must be tested for cleanliness and how contamination must be measured. Think of visual inspection under UV light, residual gas analysis (RGA) and particle detection.

Cleanliness grades

As a forerunner in this field, ASML has defined so-called cleanliness grades; in particular Grade 2 and Grade 4 are common. The customer prescribes the classification and thus the cleanliness requirements. This includes, for example, the coolants and cleaning agents to be used, but also how products must be tested for cleanliness and how contamination must be measured. Think of visual inspection under UV light, residual gas analysis (RGA) and particle detection.

Cleanliness requirements

The cleanliness requirements mainly depend on the application of the products in question, for example whether they are used in ‘ordinary’ vacuum or in ultra-high vacuum. The most important requirements are expressed in maximum permitted values for the partial pressures of molecular contaminants and the particle concentrations per square meter of product surface for different classes of particle diameters. This in turn leads to the resources that must be used, such as a cleanroom of a certain ISO class and a suitable cleaning method.

Cleanliness requirements

The cleanliness requirements mainly depend on the application of the products in question, for example whether they are used in ‘ordinary’ vacuum or in ultra-high vacuum. The most important requirements are expressed in maximum permitted values for the partial pressures of molecular contaminants and the particle concentrations per square meter of product surface for different classes of particle diameters. This in turn leads to the resources that must be used, such as a cleanroom of a certain ISO class and a suitable cleaning method.

All expertise and facilities

Grade 4-cleaning is now fairly easy to achieve with the right installations, while Grade 2-cleaning is still a challenge, although the technology for this is developing rapidly. In our network we have all the necessary expertise and competences to supply parts according to the classifications Grade 2-Cleanliness and Grade 4-Cleanliness.

All expertise and facilities

Grade 4-cleaning is now fairly easy to achieve with the right installations, while Grade 2-cleaning is still a challenge, although the technology for this is developing rapidly. In our network we have all the necessary expertise and competences to supply parts according to the classifications Grade 2-Cleanliness and Grade 4-Cleanliness.

Chain management

Delivering according to Grade 2 is only possible if this is taken into account during the production – or even during the design – of the parts. The entire chain must be able to meet the requirements. We then only work with partners who work according to the Grade 2-standards. For example, they must use special lubricants and their operators must absolutely not touch parts with their bare hands. If they do not produce in accordance with these requirements, subsequent cleaning in accordance with the Grade 2-requirements is impossible. We therefore strictly monitor compliance with Grade 2 in our chain.

Chain management

Delivering according to Grade 2 is only possible if this is taken into account during the production – or even during the design – of the parts. The entire chain must be able to meet the requirements. We then only work with partners who work according to the Grade 2-standards. For example, they must use special lubricants and their operators must absolutely not touch parts with their bare hands. If they do not produce in accordance with these requirements, subsequent cleaning in accordance with the Grade 2-requirements is impossible. We therefore strictly monitor compliance with Grade 2 in our chain.